To guarantee safety around infinity pools, you should follow slip-resistance standards that vary by country and local regulations. Common materials include textured tiles, anti-slip coatings, and rubber mats, all tested with specific measurement techniques like the pendulum test or static coefficient of friction. Staying compliant with building codes and choosing surfaces with appropriate slip ratings is essential. Keep exploring this topic further to discover the latest standards and innovative safety solutions.

Key Takeaways

- International standards (ANSI, ASTM, ISO) specify minimum slip-resistance values, like a DCOF of at least 0.42 for wet surfaces around pools.

- Testing methods such as pendulum, ramp, and slip testers evaluate surface slip resistance and ensure compliance with safety benchmarks.

- Local building codes mandate specific slip-resistance criteria and regular testing to maintain safety around infinity pools.

- Materials like textured stone, ceramic tiles, and rugged concrete are recommended for their slip-resistant properties in wet environments.

- Regular maintenance and cleaning are essential to preserve slip-resistance levels and prevent slip-and-fall hazards around infinity pools.

Understanding the Importance of Slip Resistance Near Infinity Pools

Because infinity pools often feature wet, slippery surfaces near their edges, guaranteeing slip resistance is essential for safety. The area around your pool can become hazardous when wet, increasing the risk of slips and falls. This is especially critical since many infinity pools are built at elevated levels or with stunning edge designs that encourage close proximity. A slip-resistant surface helps you enjoy your pool without fear of accidents, protecting both swimmers and those nearby. Without proper slip resistance, you risk injuries that can be severe or even life-threatening. Implementing reliable slip-resistant measures reduces these dangers and promotes a safer environment. Ultimately, understanding and prioritizing slip resistance around infinity pools ensures peace of mind and safety for everyone using the space.

Key Materials Used for Anti-Slip Pool Surroundings

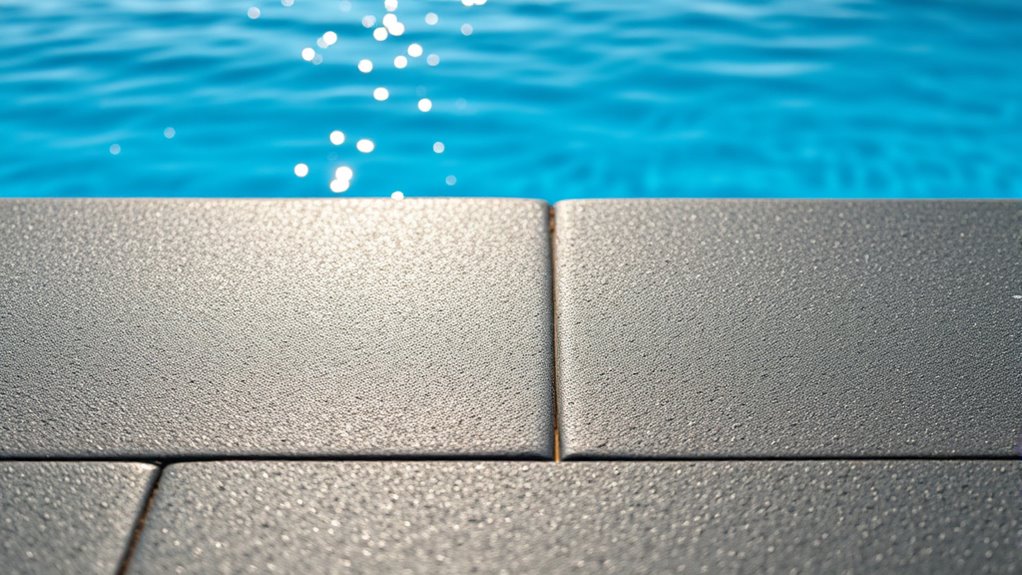

You need reliable materials for safe pool surroundings, and several options stand out. Textured stone surfaces, durable ceramic tiles, and rugged concrete finishes all offer slip-resistant qualities. Choosing the right material can make a significant difference in preventing accidents around the pool. Incorporating community engagement into safety initiatives can also enhance awareness and adherence to safety standards.

Textured Stone Surfaces

Textured stone surfaces are a popular choice for anti-slip pool surroundings because they provide natural grip and durability. Their rough texture helps prevent slips, even when wet, making them ideal for high-traffic areas around infinity pools. You’ll find options like slate, limestone, and granite, each offering unique aesthetic qualities and slip-resistant properties. These stones are naturally resistant to water damage and weathering, ensuring longevity despite exposure to sun and moisture. Installing textured stone surfaces requires careful planning to ensure even traction and prevent loose stones that could pose hazards. Regular maintenance, like cleaning and sealing, enhances their slip-resistant qualities and preserves their appearance. Additionally, the coverage area of these surfaces can be tailored to specific pool sizes, ensuring comprehensive safety. Overall, textured stone surfaces combine safety, strength, and elegance, making them a reliable choice for luxurious pool environments.

Durable Ceramic Tiles

Durable ceramic tiles are a top choice for anti-slip pool surroundings due to their toughness and versatility. These tiles resist water, stains, and wear, making them ideal for high-traffic pool areas. Their textured surfaces provide excellent grip underfoot, reducing the risk of slips and falls. You can choose from various finishes, such as matte or textured glazes, to enhance slip resistance. Ceramic tiles are also easy to clean and maintain, ensuring your pool deck stays safe and attractive over time. Additionally, they come in a wide range of colors, shapes, and sizes, allowing you to customize your pool area’s look without compromising safety. Properly selecting tiles with the right flushing mechanism ensures better performance and safety in wet environments. Overall, ceramic tiles offer a reliable, durable solution that balances style with essential slip resistance around infinity pools.

Rugged Concrete Finishes

Rugged concrete finishes are a popular choice for anti-slip pool surroundings because they provide excellent traction even when wet. These surfaces are textured intentionally to reduce slipperiness, making them safer for barefoot use and active movement. You can achieve rugged finishes through methods like broom finishing, exposed aggregate, or troweled textures, each offering varying levels of grip. They’re durable, resistant to weather and heavy foot traffic, and require minimal maintenance. Plus, concrete finishes can be customized with stains or dyes for aesthetic appeal, blending safety with style. When selecting concrete for your pool area, guarantee the surface is properly textured and maintained to prevent slips. Proper texturing is crucial in ensuring the effectiveness of rugged concrete finishes. Rugged concrete offers a practical, long-lasting solution that prioritizes safety without sacrificing design.

International Standards for Slip Resistance Testing

International standards for slip resistance testing provide a consistent framework for evaluating how surfaces perform under various conditions. These standards help guarantee safety by defining specific testing procedures and performance thresholds. Organizations like the American National Standards Institute (ANSI), ASTM International, and ISO set guidelines that manufacturers and inspectors follow worldwide. They specify test methods, such as the use of standardized pendulum or ramp tests, to measure slip resistance reliably. By adhering to these standards, you can compare surfaces accurately and determine if they meet safety requirements. This consistency is vital for pools, walkways, and other wet environments where slip hazards are common. Ultimately, international standards help you create safer surfaces and reduce slip-and-fall accidents around infinity pools and beyond.

Common Testing Methods and Measurement Techniques

To accurately assess slip resistance, you need to understand the most common testing methods and measurement techniques used in the industry. The tribometer is the primary tool, simulating foot traffic to measure the coefficient of friction. There are two main types: the slip tester and the walk-over tester. The slip tester uses a standardized rubber heel or slider that moves across the surface, providing a quantitative measurement. Walk-over testers involve a person walking over the surface under controlled conditions, recording slip incidents or friction values. Additionally, some methods utilize pendulum testers, which swing a rubber-footed arm to gauge slip potential. These techniques help guarantee your pool deck surfaces meet safety standards and provide reliable slip resistance data. Regular testing ensures that the surface remains effective in reducing slip risks, especially in indoor air quality environments where moisture can contribute to hazardous conditions.

Local Building Codes and Regulations for Pool Decks

You need to understand your local slip-resistance requirements for pool decks, as regulations vary by area. Material compliance standards make certain that your surfaces meet safety criteria, and inspections help verify these standards are maintained. Staying informed about enforcement practices keeps your pool area safe and compliant with building codes. Additionally, understanding bad slip-resistance signs can help you identify potential hazards before an incident occurs.

Local Slip-Resistance Requirements

Local building codes and regulations often set specific slip-resistance standards for pool decks to guarantee safety and compliance. These requirements vary by location but aim to reduce slips and falls around water. You should check your local codes to understand the exact standards you need to meet. Common requirements include minimum slip-resistance values, surface texture specifications, and durability criteria. Failing to adhere can result in fines, unsafe conditions, or the need for costly modifications. Be aware that some codes specify testing methods or enforce certain materials. Staying compliant ensures a safer environment for everyone.

- Minimum slip-resistance ratings required by law

- Surface texture specifications for safety

- Testing procedures mandated by local authorities

- Mandatory signage and warnings

- Inspection and certification processes

Material Compliance Standards

Material compliance standards for pool decks are enforced through local building codes that specify acceptable materials and their performance criteria. These standards ensure that deck surfaces are durable, weather-resistant, and safe for foot traffic, especially in wet conditions. Codes typically mandate the use of materials with proven slip-resistant properties, quality certifications, and proper installation methods. You must verify that materials meet fire safety, UV stability, and environmental guidelines. Manufacturers often provide compliance documentation, which you should review carefully. Local authorities may require testing reports or certifications before approving construction or renovation projects. Adhering to these standards helps prevent accidents and ensures your pool deck remains safe, compliant, and long-lasting. It is also important to consider risk assessment for potential hazards associated with different materials and installation practices. Always consult your local building department for specific material requirements applicable to your area.

Inspection and Enforcement

How do authorities guarantee pool decks meet safety and performance standards? They conduct regular inspections, enforce codes, and penalize violations to assure compliance. Inspectors verify that decks meet slip-resistance standards, checking materials, surface conditions, and installation methods. They also review documentation and perform spot tests to identify hazards. Enforcement actions include fines, mandatory repairs, or even closure if standards aren’t met. Staying compliant requires ongoing vigilance from pool owners and operators. Additionally, slip-resistance testing is essential to ensure surfaces maintain safety over time.

Recommended Slip-Resistance Ratings for Pool Areas

To guarantee safety around pools, it’s essential to follow recommended slip-resistance ratings for various surfaces. For pool decks, a dynamic coefficient of friction (DCOF) of at least 0.42 is advised to prevent slips, especially when wet. Surfaces like textured concrete, tiles, or epoxy coatings should meet or exceed this standard. Pool walkways and surrounding areas should also be slip-resistant but may have slightly lower requirements depending on foot traffic. Remember, the goal is to minimize falls and injuries, so always choose materials tested and rated for wet environments. Regular maintenance and cleaning help preserve slip-resistance qualities. Additionally, understanding local safety regulations is crucial for compliance and safety enhancements around infinity pools. By adhering to these ratings, you can considerably enhance safety and reduce liability around infinity pools and other aquatic spaces.

Design Considerations for Enhancing Safety

Design plays a pivotal role in promoting safety around pool areas. Thoughtful choices can markedly reduce slip hazards and create a secure environment. Focus on textured surfaces that provide traction even when wet, and avoid highly polished finishes that can become slippery. Incorporate adequate lighting so users can see potential hazards clearly. Use contrasting colors on edges and steps to enhance visibility. Additionally, design layouts that minimize sharp turns and obstacles, reducing the risk of falls.

- Textured, slip-resistant flooring materials

- Proper lighting for visibility

- Clear, contrasting markings on steps and edges

- Gradual slope transitions instead of sudden drops

- Minimization of clutter and obstacles

Maintenance Practices to Preserve Slip-Resistance

Regular maintenance is essential to keep slip-resistant surfaces effective over time. You should routinely sweep away debris, dirt, and algae that can reduce traction. Regularly inspect the surface for wear, cracks, or damage that could compromise slip resistance. Cleaning with appropriate solutions helps remove oils, grease, and other contaminants that may build up and create hazards. Use gentle scrubbing tools to avoid damaging the surface’s texture. Applying a slip-resistant coating or treatment as recommended by the manufacturer can restore or enhance grip. Always follow manufacturer guidelines for cleaning and maintenance products to prevent deterioration. Conducting routine inspections enables early detection of potential hazards and ensures consistent safety standards. Consistent upkeep ensures the surface maintains its intended slip-resistance, reducing the risk of accidents and prolonging the lifespan of your infinity pool’s safety features.

Innovations and Trends in Anti-Slip Technologies

Recent advancements in anti-slip technologies are transforming safety solutions across various industries. You now have access to smarter, more effective options that adapt to different environments. Innovations like textured coatings, nanotechnology, and self-cleaning surfaces improve grip and longevity. Anti-slip mats now feature advanced materials that resist wear and weather damage, while embedded sensors monitor surface conditions in real-time. Additionally, eco-friendly solutions are gaining popularity, reducing environmental impact without compromising safety. These trends ensure safer pools and walkways, especially around infinity pools where slip risks are high.

- Self-healing coatings that repair minor scratches

- Anti-slip coatings with embedded micro-roughness

- Smart surfaces with sensor integration

- Eco-friendly, biodegradable anti-slip materials

- UV-resistant and weatherproof solutions

Frequently Asked Questions

How Often Should Slip Resistance Be Tested on Infinity Pool Decks?

You should test slip resistance on infinity pool decks at least quarterly to guarantee safety, especially after heavy use or adverse weather conditions. Regular testing helps identify worn or slippery surfaces early, preventing accidents. Additionally, conduct inspections after any maintenance work or surface repairs. Consistent testing and maintenance keep the deck safe for everyone, giving you peace of mind knowing that safety standards are maintained effectively.

Are There Specific Slip Resistance Standards for Different Climate Zones?

You’ll find that slip resistance standards for infinity pool decks do vary by climate zone because weather impacts surface safety. For instance, colder regions often require more stringent testing due to ice and snow, while warmer zones focus on heat and sun exposure. It’s essential you check local regulations and manufacturer guidelines to guarantee your deck meets the specific slip resistance standards for your climate, reducing risks and ensuring safety year-round.

Can Slip-Resistant Surfaces Be Customized for Aesthetic Purposes?

Yes, you can customize slip-resistant surfaces for aesthetic purposes. You have options to choose different textures, colors, and patterns that match your design vision. Many manufacturers offer tailored solutions, allowing you to blend safety with style. By working with professionals, you guarantee the surface maintains slip resistance while enhancing the overall look. This way, you get a beautiful, safe environment that reflects your personal taste and complements your space.

What Are the Cost Implications of Upgrading to Higher Slip-Resistance Materials?

Upgrading to higher slip-resistance materials can increase your costs markedly, often by 20-50%. You’ll pay more for premium textured surfaces or specialized coatings, but these can enhance safety and durability. While initial expenses are higher, they may reduce long-term costs related to accidents or repairs. Consider your budget, safety needs, and aesthetic preferences to determine if the investment aligns with your priorities and provides value over time.

How Do User Foot Traffic Patterns Influence Slip-Resistance Requirements?

Coincidentally, your foot traffic patterns directly impact slip-resistance needs. When you notice heavy or frequent use, especially in wet areas near infinity pools, you must prioritize higher slip-resistance materials to prevent accidents. Conversely, if traffic is light or limited to dry conditions, standard surfaces may suffice. By analyzing these patterns, you can tailor slip-resistance measures, ensuring safety without unnecessary upgrades, and optimize maintenance costs effectively.

Conclusion

Did you know that slips and falls around pools account for nearly 50% of all pool-related injuries? By understanding slip-resistance standards and choosing the right materials, you can greatly reduce risks. Regular maintenance and adopting innovative anti-slip technologies ensure safety for everyone enjoying your infinity pool. Prioritizing slip resistance isn’t just about compliance—it’s about protecting your loved ones and creating a safer, more enjoyable environment for all.