To effectively control cracks with shotcrete, focus on proper surface preparation, including cleaning, roughening, and repairing any weak spots. Select suitable materials like polymer admixtures and steel fibers to improve flexibility and strength. Apply the shotcrete in layers with the right mix and technique, and continuously monitor for cracks using gauges and sensors. Proper curing and safety measures are also crucial to guarantee durability. Keep going to uncover detailed tips for flawless shotcrete application and crack management.

Key Takeaways

- Proper substrate preparation, including cleaning, roughening, and crack repair, is essential before shotcrete application.

- Use appropriate materials like fibers, admixtures, and correct mix design to enhance crack resistance and durability.

- Maintain consistent application techniques, including nozzle distance, layering, and environmental controls, to prevent cracking.

- Implement real-time monitoring with gauges and sensors to detect and address cracks early during curing and service.

- Follow strict curing procedures and protective measures to ensure surface integrity and minimize post-application cracking.

Understanding the Causes of Cracking in Concrete Structures

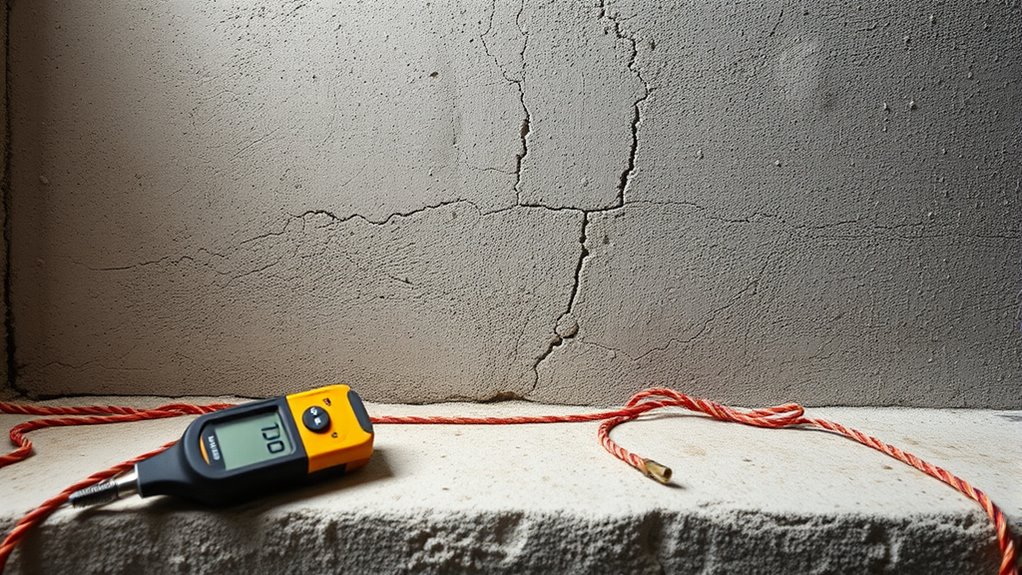

Cracking in concrete structures often results from a combination of factors that cause internal stresses. When you pour concrete, it shrinks as it cures and dries, creating tension within the material. If this shrinkage isn’t properly managed, cracks develop. Temperature changes also play a role; hot days cause expansion, while cold days lead to contraction, stressing the concrete. Load stresses from structural weight or external forces add to this, especially if the concrete isn’t designed to handle them. Additionally, improper mixing, curing, or placement can weaken the structure, making it more prone to cracking. Understanding these causes helps you anticipate potential issues and implement measures to minimize cracking, ensuring your concrete remains durable and long-lasting. Recognizing the importance of proper curing techniques can significantly reduce the likelihood of cracks forming over time.

Selecting the Right Materials for Crack Control and Shotcrete

Choosing the right materials for crack control and shotcrete is crucial to guarantee durability and performance. You need materials that resist cracking, bond well, and accommodate movement. Selecting appropriate admixtures, aggregates, and binders can make a significant difference. For crack mitigation, fiber-reinforced shotcrete often outperforms conventional mixes by controlling microcracks. The right combination ensures your structure withstands stress and environmental factors. Here’s a quick reference:

| Material Type | Key Feature | Best Use Case |

|---|---|---|

| Polymer Admixtures | Improved adhesion and flexibility | Enhancing crack resistance |

| Steel Fibers | Reinforcement and crack bridging | Structural shotcrete applications |

| Lightweight Aggregates | Reduced weight, thermal insulation | Overhead or vertical placement |

| Cement Type | Fast-setting or high-performance | Rapid repairs or high strength |

| Additives | Water reducers, accelerators | Optimizing workability and curing |

Additionally, understanding the performance characteristics of these materials helps in selecting the most suitable options for specific project requirements.

Preparing the Substrate for Optimal Shotcrete Adhesion

To guarantee ideal adhesion of shotcrete, you must start with a properly prepared substrate. Begin by removing loose or unstable material, dirt, oil, and any contaminants that could hinder bonding. Ascertain the surface is moist but not saturated; excessive water can weaken the bond, while a dry surface hampers adhesion. Roughen smooth surfaces to increase mechanical interlock, using methods like brushing or light blasting. Check for and repair any cracks, voids, or weak spots, filling them with suitable patching materials. Verify that the substrate has the proper slope and drainage, preventing water accumulation that could compromise adhesion. Proper surface preparation creates a clean, stable, and textured base, which is essential for strong, durable shotcrete application. Ensuring that the surface is properly prepared materials is crucial for optimal shotcrete adhesion and long-term performance.

Techniques for Effective Crack Prevention and Management

To prevent cracks effectively, you need to focus on proper surface preparation techniques and apply shotcrete correctly. Using the right application methods and monitoring cracks as they develop helps you catch issues early. Implementing these strategies guarantees your shotcrete remains durable and crack-free over time. Additionally, understanding the environmental impacts of construction materials and practices can help in selecting sustainable options that minimize long-term deterioration and environmental harm.

Proper Surface Preparation Techniques

Effective surface preparation is essential for preventing cracks and ensuring the longevity of shotcrete applications. Proper cleaning removes debris, loose material, and laitance, creating a strong bond. Surface roughening, such as blasting or wire brushing, enhances adhesion. Moisture control prevents weak bonding due to excess water or dryness, which can lead to cracks. Use the table below to visualize key preparation steps:

| Step | Purpose |

|---|---|

| Clean thoroughly | Remove dirt, dust, and loose materials |

| Roughen surface | Increase mechanical bonding |

| Control moisture | Ensure optimal curing conditions |

| Repair surface flaws | Fill cracks or holes before shotcrete |

| Mark crack-prone areas | Identify zones needing extra attention |

Following these techniques ensures a solid foundation, reducing crack risks and improving shotcrete durability. Additionally, understanding the cultural impact of technology can guide better application methods and community engagement.

Optimal Shotcrete Application Methods

Selecting the right shotcrete application methods is essential for minimizing cracks and ensuring structural integrity. You should focus on controlling the application’s speed and pressure to avoid over-application or segregation, which can lead to weak spots. Use proper shotcrete techniques, such as consistent nozzle distance and angle, to promote even placement and adhesion. Adjust your water-cement ratio carefully to maintain workability without sacrificing strength. Incorporate proper reinforcement placement before applying shotcrete to prevent cracking from structural movement. Additionally, applying shotcrete in layers, rather than a single thick pass, reduces stress buildup and improves bonding. Properly controlling humidity and temperature during application also helps prevent surface cracks. Understanding material properties is crucial for selecting the appropriate mix and application method that enhances durability. By following these optimized methods, you’ll enhance crack resistance and achieve durable, high-quality shotcrete.

Effective Crack Monitoring Strategies

Implementing robust crack monitoring strategies is essential for identifying potential issues early and preventing serious damage. Regular visual inspections help you spot cracks before they worsen, while installing crack gauges allows precise measurement of crack widths over time. Use strain sensors for continuous data, providing real-time alerts to movement or stress. Take photographic records to document crack progression, aiding trend analysis. Incorporate displacement monitoring to track shifts in structural elements. Guarantee that monitoring equipment is properly calibrated and maintained. By combining these techniques, you gain a thorough understanding of how cracks develop and evolve. Early detection allows you to implement targeted repairs or adjustments, reducing repair costs and extending the lifespan of your structure. Consistent monitoring is your best defense against unnoticed crack growth. Recognizing the underlying narcissistic traits of problematic behaviors can also help in addressing and managing relationships that may impact project stability or safety.

Best Practices in Shotcrete Application and Placement

To guarantee the success of shotcrete projects, proper application and placement techniques are essential. First, ensure your mix design matches project requirements, with correct water-cement ratio and additives. When spraying, maintain consistent nozzle distance and angle to achieve uniform thickness and finish. Use proper reinforcement placement to prevent voids and ensure structural integrity. Apply shotcrete in layers, allowing each to adhere properly before adding the next, which helps minimize cracks. Keep the work environment clean and free of debris, and monitor humidity and temperature to prevent premature drying or setting issues. Employing specialized equipment like airless sprayers can improve application consistency and efficiency. Consistent techniques and attention to detail during application help reduce weaknesses, improve bonding, and promote long-term durability of the shotcrete structure.

Curing and Post-Application Care for Durability

Proper curing techniques are essential to guarantee your shotcrete gains maximum strength and durability. You should also implement ongoing damage prevention methods to protect your work over time. By focusing on these areas, you can considerably extend the lifespan of your shotcrete installation. For example, employing best practices for crack control can prevent future issues and maintain structural integrity.

Proper Curing Techniques

Effective curing is essential to guarantee the long-term durability of shotcrete and crack control measures. Proper curing maintains ideal moisture, temperature, and humidity levels during the initial setting period. To do this, keep the shotcrete continuously moist with water or curing compounds that form a moisture-retaining film. Avoid letting the surface dry out or experience rapid temperature changes, as this can cause cracking. Cover the shotcrete with plastic sheeting or wet burlap to lock in moisture, especially in hot or windy conditions. Begin curing immediately after finishing and continue for at least 7 days, depending on climate and mix specifications. Proper curing minimizes shrinkage cracks, enhances strength, and ensures the shotcrete’s long-term performance and crack resistance. Dog names can serve as a useful analogy for selecting appropriate measures to maintain the integrity and appearance of the surface during curing.

Ongoing Damage Prevention

Maintaining the integrity of shotcrete after initial curing requires ongoing attention and care. You should regularly inspect the surface for cracks, chips, or signs of deterioration, addressing issues promptly to prevent further damage. Keep the shotcrete moist during the early stages, especially in hot or windy conditions, to prevent premature drying that can cause cracks. Avoid heavy traffic or loads on the surface until it’s fully cured and hardened. Additionally, protect the shotcrete from freeze-thaw cycles and chemical exposure that can weaken its structure over time. Proper drainage around the application site helps prevent water infiltration, which can cause deterioration. By consistently monitoring and maintaining the shotcrete, you ensure its durability and longevity, reducing the risk of ongoing damage and costly repairs.

Quality Assurance and Inspection Methods

To guarantee crack control and shotcrete performance meet project standards, thorough quality assurance and inspection methods are essential. You need to verify every step, from material mixing to application, ensuring compliance with specifications. Regular testing helps identify issues early, preventing costly repairs later. Inspection should include monitoring surface porosity, bond strength, and thickness to confirm proper application. You should also track environmental conditions during spraying, as temperature and humidity affect curing and crack development. Proper documentation of inspections ensures accountability and provides a record for quality control purposes. Consistent oversight allows you to catch deviations before they become problems, maintaining the integrity of the shotcrete and minimizing crack risks. This proactive approach ensures your project meets safety, durability, and performance standards.

Innovations and Latest Technologies in Shotcrete and Crack Control

Recent advancements in shotcrete technology are transforming how crack control is managed, offering more reliable and efficient solutions. You now have access to high-performance fibers, such as synthetic and steel reinforcements, which strengthen shotcrete and minimize cracking risks. Automated spraying equipment ensures consistent application, reducing human error and improving quality. Innovations like real-time monitoring sensors enable you to detect stress and crack development early, allowing prompt intervention. Additionally, new admixtures improve adhesion and flexibility, accommodating movement without cracking. Use of advanced curing techniques, such as rapid-curing agents and temperature control systems, enhances durability and surface integrity. These technologies help you achieve tighter crack control, extend the lifespan of structures, and optimize project efficiency with less rework and maintenance.

Safety Considerations During Shotcrete Operations

Ensuring safety during shotcrete operations is essential to protect workers and prevent accidents on site. You need to be aware of potential hazards and follow proper safety protocols at all times. Always wear appropriate personal protective equipment, including masks, goggles, gloves, and helmets. Guarantee proper ventilation to avoid inhaling harmful dust and fumes. Conduct thorough site assessments before starting, and verify equipment is in good working order.

- Use barrier tapes and warning signs to keep unauthorized personnel away

- Maintain clear communication among team members for coordinated operations

- Regularly inspect hoses, nozzles, and machinery to prevent malfunctions

Frequently Asked Questions

How Does Climate Affect Crack Control Strategies in Shotcrete?

Climate critically impacts your crack control strategies in shotcrete. If you’re working in cold environments, you need to use heated or insulated mixes to prevent freeze-thaw damage. In hot, dry climates, controlling moisture and curing properly is essential to prevent cracking from rapid drying. Humid conditions require careful mix adjustments to reduce excess moisture. By adapting your techniques to climate conditions, you can improve crack resistance and guarantee long-lasting shotcrete results.

What Are the Environmental Impacts of Different Shotcrete Materials?

You’ll want to weigh the environmental impacts of shotcrete materials carefully. Traditional portland cement emits considerable carbon dioxide, contributing to climate change. Eco-friendly alternatives like fly ash or silica fume reduce emissions and resource use, helping you lessen your ecological footprint. Using recycled or locally sourced materials can further lower environmental costs. By choosing greener options, you promote sustainable construction, safeguarding the environment while still achieving durable, effective shotcrete results.

How Can I Improve Worker Safety During Shotcrete Application?

To improve worker safety during shotcrete application, you should ensure proper training on equipment and safety procedures, always wear appropriate personal protective gear like respirators, gloves, and eye protection, and maintain good ventilation to reduce inhalation risks. Regularly inspect tools and equipment for safety, follow established protocols, and communicate clearly with your team. Keeping a clean work area and being aware of potential hazards also markedly enhance safety during shotcrete application.

What Maintenance Practices Extend Shotcrete Longevity?

Maintaining shotcrete is like tending a garden—you need regular care to guarantee its longevity. You should inspect surfaces regularly for cracks or deterioration, clean the wall surfaces to prevent buildup, and address any issues promptly to prevent further damage. Applying protective coatings and sealing joints also helps shield the shotcrete from moisture and environmental damage. Consistent maintenance keeps your shotcrete durable, saving you money and effort in the long run.

How Do Cost Considerations Influence Crack Control Choices?

Cost considerations critically influence your crack control choices because budget constraints may lead you to select less expensive materials or techniques. You might opt for simpler reinforcement methods or fewer preventative measures to save money, but this could risk higher long-term repair costs. Balancing initial expenses with durability is essential, so you should evaluate the long-term benefits of more effective crack control options to guarantee your investment lasts and minimizes future repairs.

Conclusion

By applying these best practices, you can greatly reduce cracking and guarantee long-lasting concrete structures. Did you know that proper crack control methods can extend a concrete project’s lifespan by up to 50%? Staying vigilant with material selection, preparation, and curing not only saves time and costs but also enhances safety. Keep innovating and inspecting regularly to maintain top-quality shotcrete applications—your structures depend on it for durability and performance.