To mitigate rooftop noise and vibrations, focus on strategic building design, such as using sound-absorbing materials, barriers, and proper sealing to block sound transmission. Select vibration isolators, resilient mounts, and resilient supports for mechanical equipment to prevent vibrations from transferring. Regular maintenance and operational adjustments also help reduce disturbances. Implementing these targeted approaches can markedly lower rooftop noise and vibrations—continue exploring to discover more effective strategies.

Key Takeaways

- Use vibration isolators like resilient mounts and elastomeric pads tailored to equipment vibration profiles.

- Incorporate soundproofing materials and barriers such as acoustic screens and green roofs to absorb and block noise.

- Seal joints, vents, and skylights to prevent sound leaks and air-borne noise infiltration.

- Design roof structures with sound-absorbing materials and layered insulation to enhance soundproofing.

- Regularly maintain and balance rooftop equipment to minimize vibrations and ensure effective noise control.

Common Sources of Rooftop Noise and Vibrations

Many common rooftop activities and equipment generate noise and vibrations that can disturb building occupants. HVAC systems, especially large fans and compressors, produce constant hums and mechanical sounds. Rooftop antennas and communication devices can generate buzzing or clicking noises during operation. Mechanical equipment like pumps, chillers, and cooling towers often create loud droning sounds and vibrations that travel through the structure. Solar panels and associated inverters may emit high-pitched noises, particularly during startup or operation. Additionally, rooftop recreational areas with music systems or outdoor machinery can contribute to elevated noise levels. These sources, if not properly managed, can lead to discomfort for occupants below and potential complaints. Understanding these common noise sources is essential for developing effective mitigation strategies.

Impact of Building Structure and Design on Noise Transmission

The building’s structure and design play a vital role in how noise travels through your rooftop. Choosing the right materials, implementing effective roof barriers, and separating floors can greatly reduce sound transmission. Understanding these elements helps you create a quieter, more comfortable environment. Additionally, incorporating soundproofing techniques inspired by astrological compatibility principles can enhance overall noise mitigation efforts.

Structural Materials’ Soundproofing

Building structures play a crucial role in controlling noise transmission, as the choice and arrangement of materials directly influence how sound travels through a rooftop. Using the right materials can markedly reduce noise infiltration and improve soundproofing. Here are four effective strategies: 1. Incorporate dense materials like concrete or brick to block sound pathways. 2. Use mass-loaded vinyl or acoustic barriers to absorb vibrations. 3. Install resilient mounts or decoupling elements to isolate structural elements. 4. Add layers of soundproof drywall or acoustic panels within the structure. Additionally, understanding the building design can help optimize the placement and effectiveness of these soundproofing methods.

Roof Design and Barriers

Roof design and barriers considerably influence how noise travels from external sources into a building. A well-designed roof with sound-absorbing materials can markedly reduce noise infiltration. Incorporating barriers such as parapets, acoustic screens, or green roofs helps block and deflect sound waves. The shape and slope of the roof also matter; steeper angles can deflect noise away more effectively. Proper sealing of joints, vents, and skylights prevents sound leaks. Additionally, using layered roofing systems with insulation layers enhances soundproofing. You should consider these design elements early in planning to minimize rooftop noise impacts. Optimizing roof structure and barriers involves understanding sound transmission, which can significantly improve acoustic insulation. By implementing these strategies, you create a more acoustically insulated environment, protecting interior spaces from external noise disturbances.

Building Floor Separation

Understanding how floor separation influences noise transmission is essential for creating quiet indoor environments. The way your floors are designed and constructed can substantially reduce sound transfer. Here are four key factors to consider:

- Material Choice: Use dense, resilient materials like concrete or specialized acoustic boards to dampen sound.

- Decoupling Structures: Incorporate isolation mounts or resilient channels between floors to prevent vibration transfer.

- Floor Thickness: Thicker floors provide better sound insulation by reducing vibrations and airborne noise.

- Seal Gaps: Ensure all joints and penetrations are properly sealed to prevent sound leaks. Additionally, understanding cultural intelligence can help in designing spaces that cater to diverse acoustic preferences and sensitivities.

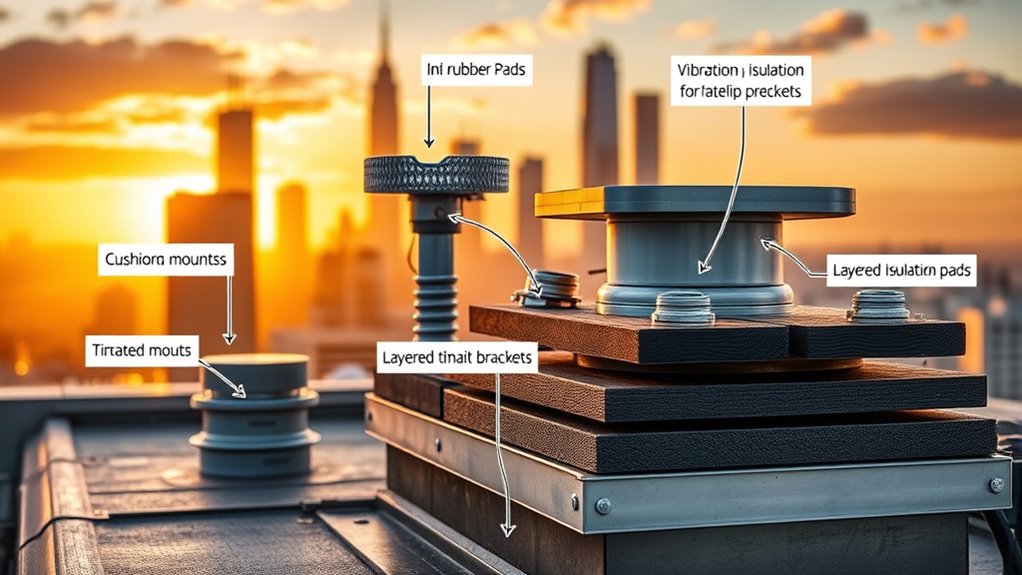

Selection of Isolation Materials and Mounts

How do you choose the right isolation materials and mounts to effectively reduce noise and vibrations? First, consider the type and intensity of vibrations or noise you need to control. For low-frequency vibrations, use resilient mounts or elastomeric pads that absorb energy effectively. For higher frequencies, materials like rubber or foam can dampen sound transmission. Pay attention to material properties such as damping capacity, durability, and temperature resistance. Guarantee the mounts can support the weight and operational loads of your equipment without compromising stability. Compatibility with your rooftop environment is also vital, especially resistance to weather and UV exposure. Finally, select mounts that are easy to install and maintain, ensuring long-term performance and consistent noise and vibration reduction. Recognizing the relationship between vibration frequencies and material selection can further optimize your isolation strategy.

Mechanical Equipment Vibration Control Techniques

To effectively control vibrations from mechanical equipment, you need to implement targeted techniques that minimize transmission to the surrounding structure. First, mount equipment on vibration isolators like elastomeric pads or spring mounts to absorb shocks. Second, incorporate flexible couplings to reduce vibration transfer through connected pipes or ducts. Third, use base isolators or resilient supports to decouple heavy machinery from the building foundation. Fourth, regularly maintain and balance equipment to prevent excess vibrations caused by imbalance or wear. Additionally, selecting appropriate vibration damping materials helps enhance overall vibration reduction. These strategies help keep vibrations contained, preventing them from propagating through the building structure and causing noise or damage. By applying these techniques, you guarantee a quieter, more stable rooftop environment, minimizing disruptive vibrations and extending equipment lifespan.

Installing Barriers and Enclosures for Noise Reduction

Installing barriers and enclosures is a highly effective way to reduce rooftop noise levels, especially around noisy mechanical equipment. By constructing solid barriers, you can block direct sound paths, preventing noise from traveling to surrounding areas. Enclosures made of sound-absorbing materials further dampen noise emissions, creating a quieter environment. When designing barriers, consider their height, placement, and distance from the source to maximize effectiveness. Ensure that enclosures allow proper ventilation to prevent overheating of equipment while maintaining sound insulation. Proper installation is key; gaps or weak points can compromise performance. Using barriers and enclosures not only reduces noise but also helps comply with local noise regulations. This approach is a practical, cost-effective way to enhance rooftop noise management and protect building occupants and neighbors. Incorporating sound-absorbing materials into enclosure design can significantly improve noise reduction outcomes.

Maintenance and Operational Practices to Minimize Disturbances

Regular maintenance and careful operational practices are essential for minimizing rooftop noise and vibrations. Staying proactive helps identify issues early and prevents increased disturbances. Here are four key practices to follow:

- Schedule regular inspections of rooftop equipment to detect loose components or worn parts.

- Lubricate moving parts frequently to reduce friction and noise.

- Ensure equipment is properly balanced, avoiding unnecessary vibrations.

- Limit operational hours for noisy machinery during sensitive periods or when occupancy is high.

- Incorporate industry-standard vibration mitigation techniques to further enhance noise reduction efforts.

Regulatory Standards and Best Practices for Noise and Vibration Mitigation

Understanding the legal noise limits and vibration control standards helps you stay compliant with regulations. Following best practice guidelines guarantees effective mitigation and safety. By prioritizing these standards, you can better manage rooftop noise and vibration issues efficiently. Additionally, incorporating community feedback on noise mitigation strategies can provide valuable insights into real-world effectiveness.

Legal Noise Limits

Legal noise limits set by regulatory standards serve as essential benchmarks for ensuring that rooftop noise and vibration levels remain acceptable within communities and work environments. These limits vary by location, purpose, and time of day, influencing your mitigation strategies. To stay compliant, you should consider:

- Monitoring noise levels regularly with calibrated instruments.

- Understanding local ordinances and permissible decibel ranges.

- Implementing noise barriers or absorptive materials to reduce sound transmission.

- Adjusting equipment operations during sensitive hours to minimize disturbance.

- Recognizing that creativity can be cultivated by anyone, regardless of skill level, which may inspire innovative solutions to noise mitigation challenges.

Vibration Control Standards

Vibration control standards provide essential guidelines and best practices for mitigating noise and vibrations from rooftop equipment. These standards establish permissible vibration levels, measurement methods, and testing procedures to guarantee safety and comfort. Regulatory bodies like OSHA, ANSI, and ISO set limits that manufacturers and building managers must follow to prevent structural damage and reduce occupant discomfort. Compliance with these standards involves selecting equipment that meets specific vibration criteria and implementing control measures such as isolators, dampers, and flexible mounts. Staying current with evolving standards helps you avoid penalties and legal issues. By adhering to vibration control standards, you create a safer, quieter rooftop environment, ensuring your equipment operates efficiently while minimizing disturbance to building occupants and neighboring structures.

Best Practice Guidelines

Implementing effective noise and vibration mitigation on rooftops requires adherence to regulatory standards and best practices that guide equipment selection and installation. To guarantee success, follow these guidelines:

- Stay compliant with local codes and industry standards, such as OSHA or ASHRAE, for safety and environmental requirements.

- Use certified vibration isolators and soundproof materials proven to reduce transmission effectively.

- Perform regular inspections and maintenance to ensure all mitigation measures remain effective over time.

- Coordinate with manufacturers and experts to select equipment that meets specific noise and vibration limits.

Frequently Asked Questions

How Can Rooftop Noise Impact Building Occupants’ Health and Productivity?

Rooftop noise can considerably affect your building occupants’ health and productivity by causing stress, fatigue, and difficulty concentrating. Constant exposure to loud or disruptive sounds can lead to increased blood pressure and sleep disturbances, reducing overall well-being. When occupants are distracted or uncomfortable, their focus and efficiency decline, impacting work quality. Managing rooftop noise is essential to create a healthier, more comfortable environment that supports productivity and occupant satisfaction.

Are There Eco-Friendly or Sustainable Isolation Materials Available?

Yes, eco-friendly and sustainable isolation materials are available. You can choose options like recycled rubber, cork, hemp, or natural fiber composites, which reduce environmental impact and offer excellent sound and vibration dampening. These materials are renewable, biodegradable, and often contain fewer toxic substances. By selecting sustainable solutions, you contribute to environmental conservation while maintaining effective noise and vibration control on rooftops.

What Are the Cost Implications of Various Vibration Mitigation Strategies?

Vibration mitigation strategies are like tuning a delicate instrument; the cost varies with complexity. Simple rubber pads cost a few hundred dollars, while advanced floating slabs or active systems can reach into the thousands or more. You might find eco-friendly options slightly pricier upfront but they offer long-term savings and sustainability. Weighing these costs against your project’s needs helps you strike the right chord for effective, budget-conscious noise control.

How Does Climate Influence the Effectiveness of Noise Barriers?

Climate profoundly influences the effectiveness of noise barriers; in hot and humid conditions, moisture can degrade materials, reducing their sound insulation properties. Conversely, in cold climates, frost and snow accumulation can diminish barrier performance or cause structural damage. You should select weather-resistant materials and design barriers with proper drainage and insulation. Regular maintenance is essential to guarantee barriers remain effective across varying climate conditions, ultimately providing consistent noise mitigation.

Can Smart Technology Be Integrated Into Vibration and Noise Control Systems?

Did you know that smart technology can reduce noise levels by up to 30%? You can definitely integrate smart systems into vibration and noise control setups. These systems use sensors and AI to monitor and adjust noise and vibrations in real time, optimizing performance. By doing so, you guarantee quieter, more effective isolation, especially in dynamic environments. This integration makes your noise control smarter, more responsive, and highly adaptable to changing conditions.

Conclusion

By implementing these rooftop noise and vibration isolation strategies, you can transform your building’s rooftop into a silent sanctuary amidst a bustling cityscape. Think of it as giving your structure a pair of ears that listen but remain untroubled by external chaos. When you select the right materials, design thoughtfully, and maintain proper practices, you’ll effectively dampen disturbances, creating a peaceful environment that stands resilient like a fortress against unwelcome noise.